TECHNOGENIC MINERALS IN THE WASTE ROCK HEAPS OF

ESTONIAN OIL SHALE MINES

AND THEIR USE TO PREDICT THE ENVIRONMENTAL IMPACT OF THE WASTE

Department of Chemical Engineering and Technology

Royal Insitute of Technology

Stockholm, S-10044 Sweden

&

Institute of Geology

University of Tartu

46 Vanemuise, Tartu 51014, Estonia

The newly formed minerals inside the waste rock heaps of

Estonian oil shale mines were studied using X-ray diffraction analysis and

scanning electron microscopy. In the unburnt heaps, the only detectable new

solid phases were ferric oxyhydroxide and gypsum. In the burnt heaps, however,

a large number of technogenic minerals were found, including lime, periclase,

portlandite, brussite, calcite, aragonite, leucite, diopside, gehlenite,

wollastonite, anhydrite, ettringite, hematite, tobermorite, larnite and

spurrite.

The

reasons for spontaneous combustion include heap size and shape, but importantly

also the heterogeneities, especially gravitational fractionation of the rocks

during the disposal. The areas where the shale remains not fully oxidised were

found, characterised by the presence of oil in the surface layer and layers of

amorphous carbon on the waste rock lumps. The negative environmental impacts of

the burnt heaps, including leachate with high alkalinity and sulfate content,

as well as oil plumes, may become evident after decades after burning only,

because the temperature inside the heaps decreases very slowly.

Introduction

Estonian oil shale mines produce kukersite for

processing and power generation. In all of these operations, large amounts of

solid residues are produced. About a third of the rock mass excavated by

underground mining is the waste rock, separated during enrichment and disposed

in heaps with the height of several tens of meters. The mining peaked in early

1980’s when about 7-8 Mt waste rock was disposed each year. By 1998, about 200

Mt of the waste rock was disposed in heaps.

In order to understand the

impact of the waste rock on the environment, the study of the solid phases of

the waste is needed. These solid phases are here named the technogenic

minerals, although the process of generation of many of them is analogous to

the natural geological processes, such as thermal metamorphism and chemical

sedimentation from oversaturated water solutions. The technogenic minerals and

their changes in time determine the quality of the leachate leaking from the

waste, with the possibility of being directly responsible for water pollution.

The mineral composition of the

kukersite waste has not been a subject of an extensive research. The reason is

that the waste rock undergoes small chemical changes only, mainly because of

the oxidation of pyrite, without causing serious environmental problems. So,

the composition of the waste rock is approximated to the unchanged shale and

limestone. However, some of the waste rock heaps have suffered spontaneous

combustion, totally changing the composition of solids.

The aim of this study was to

document the solid phase composition of the altered waste rock, especially that

of the burnt heaps, together with the geochemical analysis of the processes of

change. The study assists to work out the guidelines on the hazardousness and

water pollution potential of the waste rock.

Materials and methods

The samples of the waste rock were taken and

analysed by means of X-ray diffraction during 1988-1998. The XRD data were

collected scanning unoriented powdered samples with DRON-0.5, DRON-3M and

Siemens diffraction systems using FeK and CuK

and CuK radiation. The

mineralogy of the unchanged oil shale was analysed quantitatively using the

methods described by Utsal in 1984 [1]. The sample of the black surface layer

from the Kukruse burnt waste rock heap was also analysed using PHILIPS XL30

scanning electron microscope, equipped with the energy dispersive spectrometry

system.

radiation. The

mineralogy of the unchanged oil shale was analysed quantitatively using the

methods described by Utsal in 1984 [1]. The sample of the black surface layer

from the Kukruse burnt waste rock heap was also analysed using PHILIPS XL30

scanning electron microscope, equipped with the energy dispersive spectrometry

system.

The computer code PHREEQC [2] and the Wateq4 database [3] were used to

characterise some geochemical interactions in the water phase.

Mineralogy of kukersite

Kukersite is at present the only economically

used oil shale in Estonia and belongs to the general category of carbonate-rich

shales. The organic matter is yellowish-brown to dark-brown kerogen containing

algal remains with the size between 10-40mm [4]. Values of the kerogen

content of productive seams are ranging between 30-60 %.

The estimations of the mineral composition

calculated for 48 samples from different kukersite seams of the mining area of Aidu opencast mine are presented in

Table 1. The main carbonate mineral is calcite. Dolomite occurs in subordinate

amounts, usually not exceeding 5 %. Close to deep faults, however, dolomite has

often replaced nearly all the calcite [5]. The terrigenous component is

presented by silt-size quartz, feldspar and clay minerals - illite with traces

of chlorite. The content of pyrite is 1-3 %.

Table 1. Main minerals

and kerogen, and their content

in productive seams A-F of kukersit (dry weight)

Mineral

|

Formula |

Wt.% range |

Average |

Mol |

Quartz

|

SiO2 |

3-11 |

4.8 |

0.80 |

|

Orthoclase |

KAlSi3O8 |

1-5 |

3.1 |

0.11 |

|

Illite |

K0.6Mg0.25Al2.3Si3.5O10(OH)2 |

4-17 |

9.1 |

0.24 |

|

Chlorite |

(Mg,Fe2+,Fe3+)6 ·

AlSi3O10(OH)8 |

0-2 |

0.4 |

»0.01 |

|

Pyrite |

FeS2 |

1-3 |

1.6 |

0.13 |

|

Calcite |

CaCO3 |

25-50 |

39.0 |

3.9 |

|

Dolomite |

CaMg(CO3)2 |

0-5 |

1.7 |

0.092 |

|

Kerogen |

(Mol.%) C 39, H 57, O 3.8, N 0.18, S 0.39 |

32-52 |

40.3 |

|

Formation of Technogenic Minerals

Unburnt Waste Rock Heaps

The waste rock contains 3-6 % of kukersite [6],

the remainder being limestone originating from the layers intercalating with

the kukersite seams. The main chemical reaction inside the waste rock heaps is

oxidation of pyrite, followed by the buffering of the acidity by limestone,

precipitation of ferric oxyhydroxide and, in the case of high amount of pyrite

oxidised per kg of available water (>0.008 mol/kg, [7]), also gypsum. The

buffering reaction is fast and no acidification is caused, as the amount of

calcium and magnesium carbonates available exceeds the amount that is needed to

buffer the acidity by about 400-800 times. Eventually, the carbonate content of

kukersite itself exceeds the needed amount 10-20 times. The leachate of the

waste rock heaps is, therefore, slightly alkaline (pH 7.5-8.5), with

Ca2+ and Mg2+

being the main cations, and ![]() the main anions. The

main reactions are:

the main anions. The

main reactions are:

(1) oxidation of pyrite and precipitation of ferric oxyhydroxide:

FeS2 + 3.75O2

+ 3.5H2O __> Fe(OH)3 + 4H+ + 2![]()

(2) buffering of the acidity by carbonates

in limestone (x >0.75 for calcite

and x ~ 0.5 for dolomite):

(CaxMg1-x)CO3

+ 2H+ __> xCa2+ + (1-x)Mg2+ + CO2 + H2O

(3) dissolution of carbonates by CO2:

(CaxMg1-x)CO3

+ CO2 + H2O __> xCa2+ + (1-x)Mg2+

+ 2![]()

(4) precipitation of gypsum:

Ca2+ + ![]() + 2H2O __> CaSO4 · 2H2O

+ 2H2O __> CaSO4 · 2H2O

Burnt Waste Rock Heaps

The main reason why a waste rock heap starts to

burn is spontaneous combustion, caused by too steep slopes, too large height of

the heaps, as well as too big proportion of the oil shale within the waste

rock. The role of the heterogeneities has also to be considered [8]. Although

the average concentration of pyrite is very small in the waste rock (0.05-0.1

%), it might become a significant trigger of the initial temperature rise, if

the shale is concentrated during the disposal by gravitational forces.

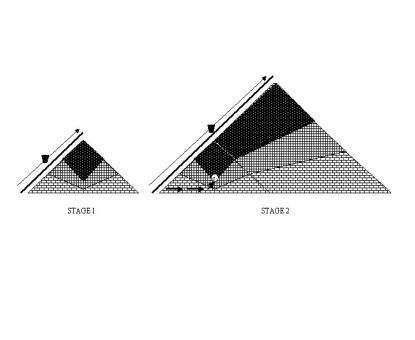

Figure 1 presents

schematically various stages in the heap formation. In stage 1, the waste rock

is deposited through dropping from the certain height. The kukersite lumps are

desintegrated much easier than limestone. Therefore, the gravitational

fractionation occurs, with the fraction with largest particle size and

permeability, as well as highest concentration of limestone accumulating in the

foot (base) area (zone 1 in Fig. 1). Zone 2 is the “intermediate” one, and in zone 3, the waste rock with

smallest particle size and therefore largest oil shale content, as well as

lowest permeability, accumulates. In stage 2, the transport road is

continuously extended and the fractionation occurs along the new slope.

Fig. 1. Formation of a waste rock heap containing oil shale and

limestone.

Stage

1: disposal from the transport system; Stage 2: disposal through continuous

extension of the transport system; Point C

– the most probable point for the start of spontaneous combustion

Regarding spontaneous

combustion of the heap, the area C in

Fig. 1 is the most critical one. Firstly, the concentration of fine-grained oil

shale is so large that fastly oxidising fine-grained pyrite may serve as a

trigger for the initial temperature rise, increasing the temperature of the

waste rock to the region where the organic matter starts to oxidise at high

rate. Secondly, the formation of convective air currents is supported by the

high permeability zone below. And thirdly, as the shale is deposited in C first, the incubation period should

end there also first.

During 1960’s and until mid-70’s, seven heaps

including altogether 6 Mt of the waste rock combusted spontaneously and

burned. The average burning time was about ten years and no methods of

extinguishing were successful. The improvements in disposal technology and

better enrichment of the shale have guaranteed that no new heaps have been

burning during 1980’s and 90’s, with the exception of the fires in the old Küttejőu open pit, where the waste containing oil shale has been

ignited several times.

The surface layers of three of

the burnt heaps were sampled and a drill core material of a burnt heap of Sompa mine was analysed. The main

chemical reactions in the surface layer are connected with the decomposition of

carbonates into oxides and, after the cool-down, formation of hydroxides and

again carbonates:

(5) decomposition of carbonates into lime (CaO) and periclase

(MgO):

(CaxMg1-x)CO3

__> xCaO + (1-x)MgO + CO2

(6) hydration of lime and formation of portlandite:

CaO + H2O __> Ca(OH)2

(7) hydration of periclase into brussite:

MgO + H2O __> Mg(OH)2

(8) reaction of portlandite back to calcite:

Ca(OH)2 + CO2

__> CaCO3 + H2O

The lumps of oil shale in the

waste heaps undergo the reactions between carbonate and silicate phases. The

reaction between calcite,

K-feldspar, illite, pyrite and quartz, as well as sulfur from the kerogen,

leads to the formation of technogenic minerals leucite (KAlSi2O6),

diopside (CaMgSi2O8), gehlenite (Ca2Al2SiO7),

wollastonite (CaSiO3), anhydrite (CaSO4), hematite (Fe2O3)

and lime (CaO). All these minerals were detected from the XRD patterns. These

patterns were not used for quantitative determination of the new minerals

because of the uncertainties in the coefficients of the characteristic peak

intensity ratios and poor crystallinity of the minerals. The approximate

concentrations of these minerals, however, can be calculated on the basis of

the approximate molal concentrations of the primary minerals (Tables 1 and 2).

The number of the newly formed phases that were detected (seven) corresponds to

the number of the main chemical compounds available in the system, thus the

analytically determined phases can be taken as “nominal” minerals for recalculations.

Table 2. Calculation of new minerals formed during burning of kukersit

in the surface layer of the waste rock dumps (on the basis of an average

kukersit sample)

|

minerals |

average kukersit sample

(mol/kg) |

Mr |

Wt.% |

||||||

|

|

CaO |

MgO |

Al2O3 |

SiO2 |

K2O |

Fe2O3 |

SO3 |

|

|

|

Leucite KAlSi2O6 |

|

|

|

|

|

|

|

|

|

|

Diopside CaMgSi2O8 |

|

|

|

|

|

|

|

|

|

|

Gehlenite Ca2Al2SiO7 |

|

|

|

|

|

|

|

|

|

|

Wollastonite CaSiO3 |

|

|

|

|

|

|

|

|

|

|

Anhydrite CaSO4 |

|

|

|

|

|

|

|

|

|

|

Hematite

Fe2O3 |

|

|

|

|

|

|

|

|

|

|

Lime CaO |

1.92 |

|

|

|

|

|

|

56 |

24.9 |

After cooling, lime is turned

to portlandite and a carbonate phase (either calcite or aragonite, another

modification of CaCO3), as given by reactions (6)

and (8). Anhydrite

is turned to

gypsum, but ettringite (3CaO · Al2O3

· 3CaSO4 · 31.5H2O) has been also found. The

presence of MgCO3 has not been detected.

In the drill core material

presenting the deeper parts of the burnt heap, some other minerals were

present, including larnite ( -Ca2SiO4),

tobermorite (4CaO · 5SiO2

· 5H2O),

periclase (MgO) and

spurrite (Ca5Si2O8CO3). In

the samples below 5 m depth in the drill core from the top of a conical heap,

all new minerals contained Ca except periclase. The possible explanation is,

that at higher temperature conditions, the decomposition products of not only

carbonates available in kukersite, but also limestone surrounding kukersite

react with the kukersite lumps that leads to the total domination of Ca and Mg

compounds in the mixture.

-Ca2SiO4),

tobermorite (4CaO · 5SiO2

· 5H2O),

periclase (MgO) and

spurrite (Ca5Si2O8CO3). In

the samples below 5 m depth in the drill core from the top of a conical heap,

all new minerals contained Ca except periclase. The possible explanation is,

that at higher temperature conditions, the decomposition products of not only

carbonates available in kukersite, but also limestone surrounding kukersite

react with the kukersite lumps that leads to the total domination of Ca and Mg

compounds in the mixture.

The "Black Blocks" Zones

On

the southern slope of the Kukruse burnt heap, the local conditions differing

from other parts of the heap and from the other heaps were found. Twelve years

after the burning was considered to be ended, the surface temperature in this

area was still 50 °C, the pores of the surface layer partly saturated

with the shale oil and the vegetation was destroyed. Obviously, the process of

semicoking was still continuing inside the heap. Chesnokov et al. [9] have

described similar zones and formation of graphite layers on the waste rock

lumps in waste rock heaps of Chelyabinsk coal basin, naming these zones as

“black blocks”. In the flow channels of the hot gases onto the surface, the

lumps of limestone were covered with the layer of amorphous carbon (Fig. 2).

Also, cylindrical forms of the same material with the length of up to 10 mm and

diameter of 0.10-0.15 mm were detected.

Fig. 2. Scanning electron micrographs of the amorphous carbon

cover layer consisting of sub-layers

The formation of the

Kukruse heap was analogous to that depicted in Fig. 1, with transport road

approaching from the south. Thus, the area of point C in Fig. 1 matches with the area of “black blocks” of the Kukruse

heap. Possibly, all the oil shale above the point C did not take part in the oxidation process, as the hot gases were

transported out through that material with no oxygen present, leading to the

oil production. Also, at high temperatures, the permeability of the heap slope

could be decreased. In the period of overall cooling of the dump, the process

of semicoking still continues, generating oil and forming the layers of

amorphous carbon.

Environmental Impact of the Burnt Heaps

According

to the hydrochemical analysis using computer code PHREEQC, the mineralogical

composition of the burnt heaps gives a reason to suppose that the leachate

flowing out of the heaps could be highly alkaline (pH up to 12.4) and also with

high sulfate content, as portlandite and gypsum are the most soluble minerals

among these described in this study. However, the temperature in the deeper

layers stays high for a very long time and should be monitored in order to

understand the long term impacts. From the borehole that was drilled 12 years

after the last burning evidence in Sompa, the temperatures up to 240 °C were measured at the

bottom of the hole (depth 23 m). Hence, the infiltrating water either

evaporates or is used up in hydration reactions during decades after burning,

explaining also the formation of tobermorite. Therefore, the period when the

alkaline leachate begins to be produced might be even longer, of the order of a

couple of decades after the end of burning.

The burnt heaps include zones where kerogen of

kukersite is not totally oxidised and the shale oil is still present. This

should be considered when the plans of the use or mass movement of the waste

rock is planned. Also, the movement of oil plumes may contaminate the ground

water resources.

Conclusions

1.

The

main geochemical reaction in the unburnt heaps is oxidation of pyrite, and the

only new solid phases detected were ferric oxy-hydroxide and gypsum. In the

samples from the burnt heaps, a large number of technogenic minerals were

found, including lime, periclase, portlandite, brussite, calcite, aragonite,

leucite, diopside, gehlenite, wollastonite, anhydrite, ettringite, hematite,

tobermorite, larnite and spurrite.

2.

The

geochemical calculations made on the molal basis of the unchanged and burnt

kukersite indicate that the analytically determined minerals can be used as the

“nominal” minerals describing the character of change.

3.

The

phenomenon of amorphous carbon formation in the “black blocks” zone together

with the abundance of oil in the surface layer are evidences that not all of

the kukersite is fully oxidised. The formation of the “black blocks” in certain

areas can be explained by the gravitational fractionation of the waste rock

material during disposal.

4.

The

negative environmental impact of the burnt heaps may become evident after

decades after burning only, because the temperature inside the heaps decreases

very slowly and practically no leachate is formed. The potential problems are

connected with high alkalinity, sulfate content, as well as with migration of

oil plumes.

Acknowledgements

The assistance of Prof. Enno Reinsalu and Dr.

Tarmo Kiipli during the first field work period in 1988 is greatfully

acknowledged. The comments of a reviewer, Dr. Rein Kuusik were appreciated.

References

1. Utsal, K. Comprehensive investigation of oil shale material

composition by X-ray diffrection method // Oil Shale. 1984. Vol. 1, No. 1. P.

69-80.

2. Parkhurst,

D. L. Users guide to PHREEQC – A computer

program for speciation, reaction-path, advective-transport, and inverse

geochemical calculations // USGS Water Resources Investigations Report 95-4227.

Lakewood, Colorado, 1995. P. 143.

3. Ball, J.

W., Nordstrom, D. K. WATEQ4F – User’s manual with

revised thermodynamic data base and test cases for calculating speciation of

major, trace and redox elements in natural waters // USGS Open-File Report

90-129. 1991. P. 185.

4.

Puura,

V., Bauert, H., Männil, R.

The conditions of kukersite deposition // Proceedings of International

Conference on Oil Shale and Shale Oil (ed. Zhu Yajie). Bejing, China, 1988. P.

42-50.

5. Bauert, H.,

Puura, V. Geology of the Baltic Oil

Shale Basin // Field Meeting Estonia 1990 : An Excursion Guidebook (eds. D.

Kaljo and H. Nestor) / Estonian Academy of Sciences. Tallinn, 1990. P. 40-45.

6. Voolma, E.,

Petersell, V., Güsson, Ü. Development of the plan for the extent of geological

investigations of building materials. 3/1. A study of the solid waste of

enrichment factories, low-quality sands and the profitability of mining granite

// Report of the Tallinn division

of the Geological Survey of ESSR. 1981 [in Russian].

7. Puura, E. Weathering of mining waste rock containing alum shale

and limestone : A case-study of the Maardu dumps, Estonia; PhD thesis /

Department of Chemical Engineering and Technology, Royal Institute of

Technology. Stockholm, 1998. P. 136.

8. Puura, E.,

Pihlak, A. Oxidation of Dictyonema shale

in Maardu mining waste dumps // Oil Shale. 1998. Vol. 15, No. 3. P. 239-267.

9.

Chesnokov,

B. V., Bazhenova, L. F., Shcherbakova, E. M., Mihal, T. A., Deryabina, T. N.

Mineralogy of the burnt dumps of the Chelyabinsk coal basin

/ Academy of Sciences of the USSR, Ural Science Centre. - Sverdlovsk, 1987. P.

70 [in Russian].